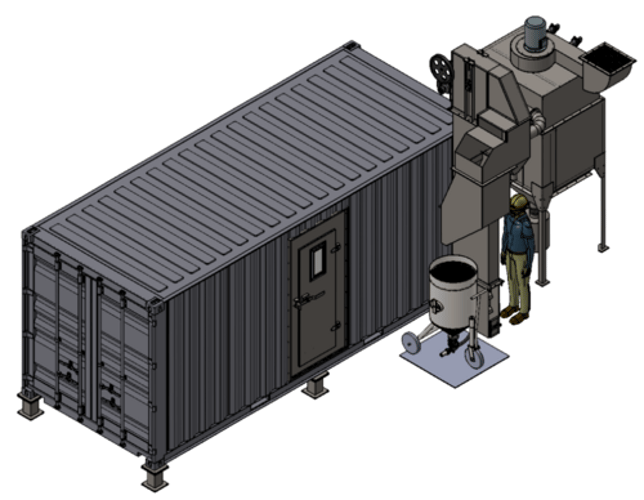

The product is a complete sandblasting room system, specifically made from a converted 20ft shipping container. It is designed for industrial use and manufactured in India. It provides an economical complete blast room solution that is watertight and it is transportable for use anywhere inside or outside for maximum flexibility. The system includes all necessary equipment for sandblasting operations and is suitable for commercial and industrial applications. Includes lights and rubber curtains inside the blast room. With a blast pot, blast hose and controls for the operator. It has a sweep in hole with a media recycling bucket elevator with air-wash separator and cartridge dust collector with a blower. Can be used with all kinds of blast media including steel shot or grit!

Standard 20 foot shipping container converted to a blast room system with these features:

1) Room ventilation to cartridge dust collector

2) Rubber curtains

3) Proper LED blast room lighting

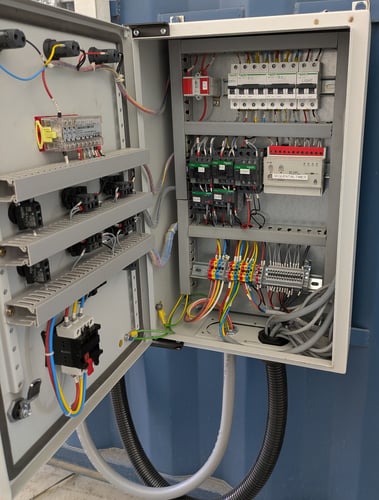

4) Advanced AC electric control box 460V, 3PH, 60HZ, 15.7 total amps

5) Container lifting legs (6) allowing easy sweep in media recovery below floor

6) Bucket elevator with air-wash and media storage hopper for proper recycling of abrasive

7) Cartridge dust collector for air-wash

8) 5cu ft blast pot with blasting hose and tungsten carbide nozzle with dead man on/off control

9) Operator blasting safety suit with gloves

10) Operator helmet air fed Nova 3 - CE market of equivalent

Everything you need to get blasting now! Just supply the electrical power, compressed air and blast media!

Compressed air required: 135 CFM

Electrical requirements: 480V, 3 Phase, 60 HZ with 15.7A total current needed (so 20A breaker).

Some additional information....BRIEF WORKING OPERATION:

- The job is placed inside the blast room and the blasting operation is carried out manually by the operator. Used abrasive falls on the floor and can be swept manually into the feed hole provided inside the blast room. From the feed hole the abrasive is lifted by the bucket elevator and drops through the air-wash lip separator system. This abrasive recovery system removes by suction fines/dust/broken media/etc from the blast media, and draws it through duct work to the dust collector. The media then falls into the storage hopper, and finally feeds into the portable blast pot where it is ready to go through the blast hose and nozzle for blasting.

- The dust and fines from the room is sucked and is carried into the dust collector and clean air is discharged into the atmosphere.

Following are the major components supplied with this 20ft blast container system:

- 20ft Blast room enclosure as standard shipping container box

- Man doors – Hinge type on side wall

- Front main doors-hinge type duly rubber lined

- Rubber lining with hangers for three side walls of the container

- Illumination with wiring & switch panel

- Bucket elevator and air wash type media separator system

- Portable blasting pot & operator’s safety wear suit

- Cartridge filter type dust collector with ducting, wiring and control panel

- Exhaust fan